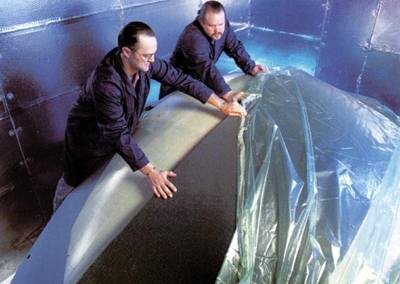

Composite Radomes & Reflectors

Antenna Associates has the technical expertise and manufacturing capabilities to produce your composite part from data, concept or from an existing part.

Using existing data, we can select proper materials and processes for your application. Using an existing part, we can reverse engineer an improved replacement part. If you only have a concept, we can design and manufacture a part that will meet your electrical and mechanical requirements.

Our engineering staff selects materials from the finest composites materials available, such as Kevlar®, Carbon and High Strength Glass. Material properties such as electrical loss, mechanical strength and acoustical properties are some of the criteria our engineers will use to select your composite material.

Additional components such as Reflective Material, Foam, Honeycomb Cores and frames can also be incorporated into your part.

Manufacturing Techniques

Selecting the proper manufacturing technique for the project is as important as selecting the right material. Because Antenna Associates facility is equipped for all types of composite manufacturing techniques, such as; vacuum bagging, autoclaving and lamination pressing, our engineers are able to incorporate the most appropriate technique to achieve your finished part requirements.

Mold Design & Manufacturing

If you require a mold to manufacture your part, Antenna Associates can help! We can design a mold and have it manufactured by one of our many qualified vendors.

Inspection & Verification

Mechanical and Electrical testing can be provided as evidence that your part meets its specifications. Our electrical test range is available for the testing of radomes and reflectors while a CMM is available for verifying part geometries. Environmental testing is also available.

Other Services

Antenna Associates is a full service ISO9001:2000 Certified manufacturer that can handle your project from start to finish. Frame manufacturing and welding, antenna feed/reflector alignment, antenna testing and acceptance test procedures are all services we can provide for your program. Antenna Associates can provide a turnkey solution to your antenna requirements.

We offer:

- Latest Materials

- Innovative Techniques

- Integrated Cores

- Mold & Tool Design

- CMM Verification

Questions?

Contact Mr. Dana Sandquist (508) 583-3241 Ext. 26 or email Mr. Sandquist for assistance with information on Identification Friend or Foe / Secondary Surveillance Radar Antennas and IFF/SSR Antenna Systems

HEADQUARTERS

21 Burke Drive

Brockton, MA 02301

PHONE/FAX

p: (508) 583-3241

f: (508) 588-3077